Smart materials are materials that react to changes in the

environment and consistently repeat recurring behavior. In the auto industry,

there have been some recent breakthroughs in using shape-memory alloys and

polymers which have numerous application opportunities including in the

automotive, medical, aerospace, electronics and appliance industries.

Friday, 16 May 2014

The Use of Smart Materials in Automotive Applications

By Unknown

Friday, May 16, 2014

automotive applications,

automotive industry,

mechanical devices,

smart materials

Wednesday, 5 February 2014

Why Automotive Chassis Design for Weight Reduction is Important?

By Unknown

Wednesday, February 05, 2014

Automotive Weight Reduction,

Chassis Design for Weight Reduction,

Chassis Design Services,

Vehicle Weight Reduction

Weight reduction is a

priority across automotive industry today. As new regulations and industry

standards push towards achieving increased vehicle efficiency and minimizing

carbon footprint, it has become imperative for auto manufacturing companies to create

designs that minimize weight of the vehicle.

From minutest fasteners to complete vehicle architectures, modern automotive chassis design for weight reduction focus primarily on wringing out additional weight from new systems and components. At the same time, auto manufacturers are looking for innovative ways of lightening the existing vehicle designs, thus, complying with industry standards and regulations, while playing a key role towards sustainable development.

From minutest fasteners to complete vehicle architectures, modern automotive chassis design for weight reduction focus primarily on wringing out additional weight from new systems and components. At the same time, auto manufacturers are looking for innovative ways of lightening the existing vehicle designs, thus, complying with industry standards and regulations, while playing a key role towards sustainable development.

What are the Key Drivers

Facilitating Automotive Weight Reduction?

The benefits and motivations for automotive weight reduction are

abundant, though a number of barriers also exist. Typically, the key driving

factors behind switching to modern automotive chassis design for weight

reduction are discussed herewith:

- Government regulations – In most countries, auto manufacturers have to comply with strict government regulations pertaining to light-weight vehicle chassis. As the regulations are becoming more stringent, more and more manufacturers to switching to automotive weight reduction.

- Fuel economy and minimizing CO2 emissions – One of the most important reasons behind shifting to weight-reducing vehicle designs is achieving fuel economy and minimizing harmful CO2 emissions. Lighter the vehicle chassis is, better it contributes to fuel economy by delivering smooth performance. At the same time, CO2 emissions can be reduced dramatically with light-weight designs.

- Consumer behavior – Of late, more and more consumers are demonstrating a changing behavior towards lightweight vehicles, which come with significant benefits and a great value for money. Considering this changing consumer behavior, auto manufacturers are moving towards automotive chassis design for weight reduction.

- Vehicle safety – With lightweight chassis, safety of the vehicle increases considerably. And this is one important factor that has contributed towards changing consumer behavior and intensity towards manufacturing lightweight vehicles.

- Cost benefits – Manufacturing lightweight chassis, but with the superior safety guarantee ensures significant cost savings for both manufacturers and buyers.

Chassis Design and

Engineering Services:

Creating chassis design for weight reduction can be complex. Therefore,

the best way to increase efficiency and minimize costs is to outsource

specialized chassis design and engineering services. This includes:

- Concept development:

- Feasibility studies

- Package development

- Benchmarks

- Static/dynamic envelopes

- Assembly simulation

- Variant development

- Module/Component Development:

- Steering components

- Axle subassemblies and components

- Springs/shock absorbers

- Engine mounts

- Brake components

- Fuel system

- Tires and wheels

- Exhaust systems

- Front and rear axle

- Wheel brake

- Module Integration:

- Assembly studies

- Package/concept

- Considering moving parts

- Digital mock-ups

- Module system requirements

- Creating support for lightweight vehicle design on the basis of chassis variant

- Simulation/Calculation:

- Topology optimization

- Strength or stiffness

- Multi-body simulation

- Calculation models

- CFD

- Vibration

- Simulation of control systems

- Vehicle dynamics simulation

- Vehicle chassis stiffness analysis

Thursday, 23 January 2014

How Streamlined Work Flow helps Manage Automobile Design and Development Process?

By Unknown

Thursday, January 23, 2014

Automobile Design and Development,

Automobile Design Process,

Automobile Design Services,

Automobile Development Process

Automobile Design and Development is an intricate process that demands in-depth knowledge of various technology specifications and excellent understanding of industry expertise and business needs.

Whether it is about designing and developing commercial vehicles, passenger cars, rolling stock, two/three wheelers, farming and industrial automotive vehicles, or recreational vehicles, it is important to develop a streamlined work flow.

Whether it is about designing and developing commercial vehicles, passenger cars, rolling stock, two/three wheelers, farming and industrial automotive vehicles, or recreational vehicles, it is important to develop a streamlined work flow.

Typically, automobile design and development work flow encompasses the following stages:

Typically, automobile design and development work flow encompasses the following stages:

- Process Performance Modeling and Analysis

- Analyzing Safety and Control

- Analyzing Economic Performance

- Developing Basic Design Package

- Model Key Equipment

- Analyze Detailed Costs

- Develop Detailed Plant Design

- Reuse Process Models for Operations Decisions

- Reuse Process Models for Planning Decisions

- Analyze Revamp Costs

From a broader perspective, all these are stages of conceptual design and R&D, basic engineering, detailed engineering, and operation/maintenance.

The key benefits of developing a streamlined work flow for design and development process are:

- Develop a comprehensive, reliable, and accurate design

- Check whether all the stages of development and implementation conforms to the design

- Easily identify loopholes or weaknesses in the design phase and fix the issues

- Eliminates costly reworks and modifications

- The process models can be used for operations and planning decisions

- It also helps in analyzing different types of costs

- Ensuring that the project is completed within the budget and timeline provided

A well-structured work flow is integral for any automobile design process, since it aids in monitoring and reviewing performance across each stage and whether it conforms to client specifications.

Sunday, 29 December 2013

Material Selection - An Important Aspect of Vehicle Engineering

By Unknown

Sunday, December 29, 2013

Automotive Material Selection,

Material Selection,

Material Selection for Vehicle

Material selection is one of the most crucial aspects

of vehicle engineering. Earlier the choice was restricted to a select few

materials. However, manufacturers are breaking the mold and are open to

experimenting with new materials to optimize designs for light weight, low

cost, higher endurance and better form.

A recent survey elaborated several pivotal factors that are considered by engineers before selecting a material for automotive design and engineering.

Selecting the right material for automobile body

engineering and designing every other part of an automobile is important, but

not so easy. It takes a lot of efforts; an array of material analysis is done

before a material is selected.

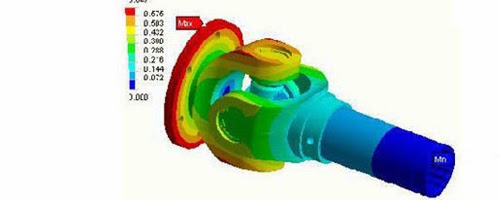

CFD analysis and FEA, are two such computational methods that can be effectively used to analyze materials. These two tools equip engineers to innovate and experiment.

Hi-Tech has infrastructural facilities and a team of experts offering expert material analysis services for automobiles. We provide detailed analysis reports and help clients select the best material for automobile design.

For more information, please contact us at http://www.hitechaes.com/contactus.php

CFD analysis and FEA, are two such computational methods that can be effectively used to analyze materials. These two tools equip engineers to innovate and experiment.

Hi-Tech has infrastructural facilities and a team of experts offering expert material analysis services for automobiles. We provide detailed analysis reports and help clients select the best material for automobile design.

For more information, please contact us at http://www.hitechaes.com/contactus.php